Replacement Without Underwater Welding

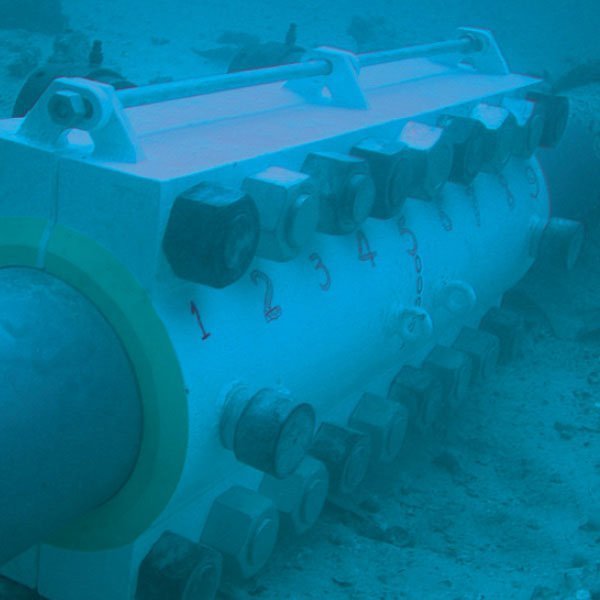

Need a fast replacement riser? PLIDCO’s Riser Weld+Ends avoids underwater welding. It is socket-welded at the surface to the new replacement riser and lowered into the water. The diver cuts off the old riser, stabs the new fitting over the cut-off pipe, then torques the clamping and thrust screws for a complete leak-proof seal without welding.

Our Riser Weld+Ends are designed to simplify the replacement of underwater riser on offshore oil and gas lines without welding underwater. The repair fitting has additional clamping and thrust screws to provide a seal for high pressure pipelines and for resisting extreme end-pull. Special installation instructions are necessary for thin wall applications.

Wondering why customers trust us? We are the only manufacturer in the industry to offer a 10-year limited warranty, which can be extended throughout the full design life of the product – a total of 25 years, on our pipeline repair and maintenance fittings.

Learn about PLIDCO’s seal options.